Webinar on OSHA’s Enforcement Initiative for Engineered Stone Fabrication and Installation Industries

December 12, 2023Australia Bans Engineered Stone

December 13, 2023Methods of Compliance (29 CFR § 1910.1053(f) and 29 CFR § 1926.1153(d)(3)).

- o Verify the dust controls and safer work methods employers use to protect workers from silica exposures above the PEL. According to the OSHA and NIOSH Hazard Alert, the following are control options for countertop manufacturing and finishing operations:

- Using water spraying systems and remote-controlled tools at the impact site where a saw or grinder generates dust.

- Large bridge or gantry-like saws usually use water sprays and can be remote-controlled for dust control and cooling.

- Hand-held angle grinders can be modified to deliver water to the point of contact with the stone.

- Wet-edge milling machines or stone routers can replace dry grinders in shops. They provide a clean edge profile with a diamond wheel.

- Using hand tools (e.g., drills, masonry saws, grinders) equipped with a shroud and a vacuum with a high efficiency particulate air (HEPA)-filter when wet methods are not practicable.

- Installing local exhaust ventilation (LEV) systems at fixed locations to capture dust at its point of origin.

- Using a combination of both water and ventilation controls, if necessary.

- Using wet sweeping or HEPA-filtered vacuuming instead of dry sweeping or compressed air.

- Replacing water and air filters as needed in accordance with manufacturer’s instructions to control dust.

- Adjusting water flow as necessary to control dust, following manufacturers’ recommendations for water flow rates.

- Pre-washing stone slabs prior to cutting.

- Implementing regular and thorough housekeeping procedures for water slurry and settled dust.

- In high exposure areas, such as where cutting or polishing work generates silica dust, provide HEPA filtered vacuums for cleaning worker clothes and water for hand, face, and hair cleaning.

- According to the OSHA and NIOSH Hazard Alert, the following are control options for countertop installation operations:

- Performing as much work as possible under controlled manufacturing conditions (i.e., using LEV) instead of at an enclosed, unventilated installation site, or performing work outdoors or in well-ventilated areas to reduce RCS dust exposure.

- Using other dust suppression methods (e.g., LEV) during operations where wet methods for dust control may not be practicable, such as on or near finished cabinets, walls, and floors.

- Using grinding and drilling tools equipped with dust shrouds coupled with LEV and a HEPA filter. Controls can be either tool mounted (drills) or attached to a vacuum system.

- Using a HEPA-filtered vacuum to clean up dust as soon as practicable.

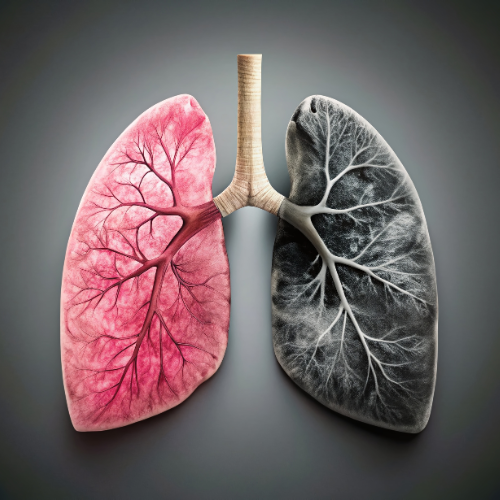

In short, to protect fabrication workers from silicosis from engineered stone, fabrication shops should use ALL of the following together: wet equipment, local exhaust ventilation, and air-fed respirators.

If you or a loved one has been diagnosed with silicosis, contact us today. You could be entitled to compensation.